by John Reid

Key Points

- The present move away from fossil fuels has largely involved electricity generation by wind and solar sources to feed existing fixed grids.

- It is envisaged that present mobile energy sources for vehicles and aircraft , i.e. fossil fuels, will be replaced by batteries or by hydrogen.

- This is likely to be a costly process because it will require replacement of the world’s entire existing vehicle fleet with newly designed vehicles adapted to the new mobile energy source and both batteries and hydrogen containers are very heavy, severely limiting the range of land vehicles and no battery powered aircraft has yet been flown.

- Both these shortcomings can be surmounted by developing sustainable (i.e. non-fossil) fuels compatible with existing vehicles and aircraft.

SAF or STF?

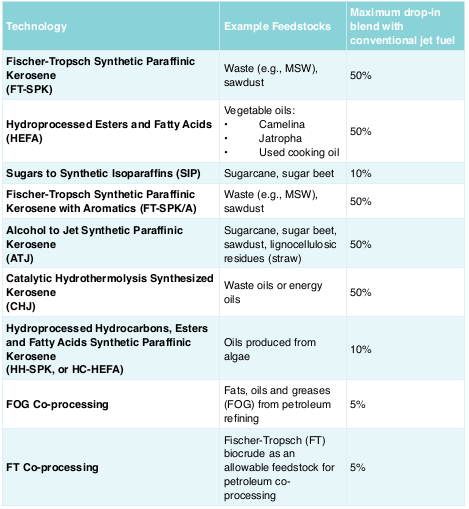

The most difficult sustainable fuel to replicate is aircraft fuel, (i.e SAF, Sustainable Aviation Fuel) but, strangely, this is the task which has received most attention. Bioenergy Australia presents a review here. Their report includes the following candidate processes presently available for the manufacture of SAF.

Note that all of these processes produce additives. None produces a fuel which can fully replace existing aviation fuel. Given the stringent requirements of aviation fuel, it may well be that a commercially viable sustainable substitute will never be found. This does not imply that the search for sustainable fuels should be abandoned. Perhaps we are trying to run before we can walk, i.e. trying to solve the most difficult problem first. At a pinch the world can get by with greatly reduced air transport without our standard of living being greatly affected. However, according to Vaclav Smil in How the World Really Works, less than half of the world’s eight billion people could continue to survive in a world without fossil fuels.

What the world really needs is STF, Sustainable Tractor Fuel.

Field Pyrolysis

For many, fossil fuel consumption is an aspect of atmospheric pollution by greenhouse gases. For others it is an issue of survival in a time of rapidly diminishing reserves. Whatever one’s perspective, there is little doubt we will soon be facing an epoch of rapidly diminishing fossil fuel availability. There is perhaps little that can be done about this issue globally; no single, one-size-fits-all panacea has yet been proposed. Different localities will need to take different paths as implied by the variety of technologies listed in the above table. Here we consider a possible path for the state of Tasmania.

With an area of 68,000 km2 and a population of 550,000, Tasmania is in a fortunate position. (Ireland, for example, has an area of 84,000 km2 and 6.6 million people.) Furthermore Tasmania has a good deal of arable land, a well established agricultural sector and a well established hydro-electric energy supply. Above all Tasmania has a well-managed eucalypt forest taking up nearly one half of its land area. It is a massive and sustainable energy resource. There is much literature on this topic, e.g. on cogeneration using forest waste and using wood chips.

Given the present price of wood chips compared with other fuels, they are already a competitive energy source. Furthermore we are not concerned here with cogeneration of electrical power but with the manufacture of sustainable fuel. Cogeneration involves the cost of transport of timber to the chipping mill and the costs of chipping and drying. Manufacturing fuel from wood can reduce handling costs by the method of field pyrolysis, i.e. heating in the absence of oxygen. This can be done onsite in the forest and has the following advantages over cogeneration, viz.:

- Charcoal produced for (smokeless) domestic heating or processing off-site by the Fischer-Tropsch process is greatly reduced in mass and volume making it cheaper to transport.

- There is no need to create or to dry wood chips.

- Waste wood can be easily processed by this method, leaving the coupe clean.

- Useful products such as eucalyptus oil and syngas can be produced onsite.

- Field pyrolysis can be carried out in conjunction with the harvesting of wood chips or quality timber.

- The process, which may be mildly polluting in terms of noise and noxious gases, is carried out in the forest, well away from population centres.

Drawbacks include the need to design and manufacture mobile field pyrolysis plants and the requirement for an onsite water supply for cooling purposes.

Conclusion

Field pyrolysis provides a method of manufacturing charcoal feedstock for sustainable fuel at a commercially competitive price. The method is suited to Tasmania and can be trialed alongside current timber harvesting operations.